TAHITIAN NONI JUICE: FROM TREE TO BOTTLE

Find out how Morinda’s flagship product is made

Have you ever wondered how Tahitian Noni Juice is made? The Tahitian Noni Juice production process is something Morinda is extremely proud of. Morinda is the only noni company in the world to own every step of the process, from tree to bottle, which means nothing moves forward until it meets the high standards of quality.

This post is here to introduce you to this magnificent process, and answer any questions you might have about the world’s most popular noni product.

Before we begin, though, we’d like to introduce you to the noni fruit. Noni fruit comes from the Morinda Citrifolia tree, and is a member of the coffee family. It grows abundantly in tropical climates, and especially on the tropical islands of French Polynesia. Its clean air, crystal clear water and nutrient-rich volcanic soil make French Polynesia the perfect place to grow big, beautiful, healthy noni fruit trees.

- First, Tahiti contains rich volcanic soil that is unusually rich and fertile.

- Second, Tahiti has clean, abundant rainfall.

- Third, Tahiti has the ideal amount of sunshine.

When Morinda selected the specific locations for harvesting noni, it did so based on a number of tests. Morinda made sure that the local soil, water, and even air all met the high standards they needed. And science supports that they chose correctly. For example, a study was conducted in which noni leaves from different locations were studied for their flavonoid concentration. Flavonoids are plant compounds that are found in almost all fruits and vegetables, and that contain health-promoting benefits. The study showed that noni leaves from Tahiti had a higher flavonoid content than leaves from Tonga, Panama or Saipan. Additional studies have compared the chemical markers of noni fruit content or the mineral content of various commercial noni juice products, finding Tahitian Noni Juice to be of a higher standard. After all, when you harvest the best noni on earth, there’s a good chance you’ll have the best noni juice on earth! And that’s why Morinda will forever be proudly linked to Tahiti.

The fruit grows year round and has such a pungent odor that it is commonly referred to as cheese fruit. This plant has been a staple in French Polynesia for thousands of years. It is prized for food and also medicinal purposes.

The steps for processing the noni fruit into Tahitian Noni Juice is not a simple task. It requires time and dedication to perfect this popular product.

Harvesting

Morinda hires native Tahitians to grow and harvest the noni fruit. Each noni farmer works with extreme care and takes great pride in their crop. None of the noni trees are treated with pesticides or chemical fertilizers, and each noni fruit is hand-picked at the peak of ripeness. Once the fruit is picked, each one is washed and inspected again to ensure the highest quality product.

Processing

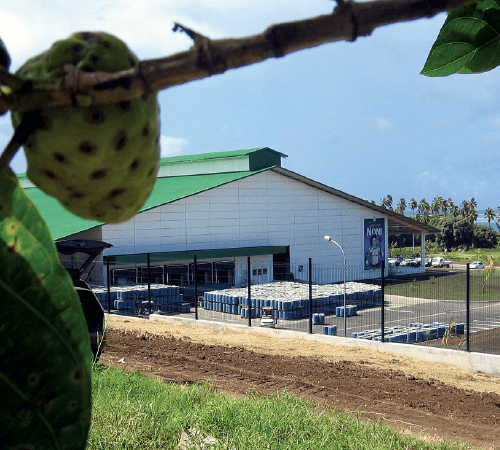

Harvesters pack the fruit into drums and ship them to Morinda’s processing plant in Mataiea, the administrative center of the Teva I Uta commune on the island of Tahiti.

It should be said that Morinda has a wonderful relationship with the government of French Polynesia. The investment in their community was put on display when Morinda signed a long-term lease with the French Polynesian government to build and run their plant in Tahiti. This state-of-the-art facility employs many local Tahitians and processes all of the noni elements: the puree, leaf, and seed.

Morinda is a huge innovator when it comes to utilizing the noni fruit to its maximum potential. Morinda is the only company that uses every element of the noni: fruit, leaf and seed. Regarding the noni seed, Morinda’s patented process of extracting oil, as well as their tremendous access to seeds (it takes 50,000 seeds to make just one ounce of oil!) means Morinda is the only company in the world that can produce this precious product.

For Tahitian Noni Juice, workers start with the noni fruit. They put it into the finisher to turn the fruit into puree by taking out all the other pieces such as seeds, stems, etc. They inspect the fruit again to guarantee the rich quality.

Pasteurization

Workers pasteurize the puree and store it according to FDA standards since the USDA considers unpasteurized fruit dangerous. The product is then pasteurized again in each bottling facility. Multi-step pasteurization is crucial, and Morinda’s proprietary pasteurization process means the product is safe to consume, while it maintains the nutritional integrity of noni.

The Tahitian processing facility then tests the noni once again to for ripeness and acidity levels. Then, it is sent out for shipping. Depending where the factory ships the product, it takes about three weeks for the product from Tahiti to arrive in the United States.

Manufacturing

When Morinda’s manufacturing facilities in the United States, China, Japan and Germany receive the product from the Tahitian processing facility, they immediately release the puree into production to turn it into Tahitian Noni Juice.

First, mixing machines add a proprietary blend of grape and blueberry juice to the noni puree for taste and added antioxidants. Then the mixture is poured into the pasteurizer again after the grape and blueberry blend is added to guarantee safety. A 36-head rotary filler pours juice into bottles as fast as 122 bottles per minute, and workers package the bottles to ship to satisfied customers around the globe.

The Company

Morinda is the noni company. Nobody knows noni like they so. Morinda owns the largest noni research facility in the world, and they are constantly making new and exciting discoveries about this miracle of nature every day. Morinda’s researchers have published dozens of studies in peer-reviewed journals, and have conducted numerous human clinical trials to learn all they can about noni. Morinda is dedicated to noni, and will make sure this product will stand the test of time.

Tahitian Noni Juice is the No. 1 noni product sold worldwide, and it’s partly due to the extreme care Morinda put into each step of the process. Their food scientists and product designers developed the process and recipe over 21 years ago, and Morinda knows it is a winner from all of the glowing reviews and compliments they receive from first-time and repeat customers.

Text & Image © Morinda.com , Kayla Fowler